Budget 350 gets a 50 horsepower tune-up

Making 356 horsepower from the Budget 350 was acceptable for its original purpose, crusing to car shows in a 1930 Model-A Ford. However, 1.0 horsepower per cubic inch isn’t exactly going to set the performance world on fire. There was definitely more power to be had so I set out to find it.

Here’s what I did:

- Upgrade the rocker arms from stock pressed metal to full roller rocker arms with poly locks.

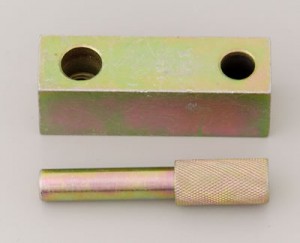

With the added pressure from the new rocker arms I needed to upgrade to a bolt in stud. Not wanting to have the stud bosses machined I stopped by my local machine shop (Engine Supply in Santa Ana Ca.) for some help. They recommended a bolt in stud used as a direct replacement for the press-in type currently in the heads. All that I needed was a stud pulled, course thread tap that matched the studs, and of course 16 studs. The use of a rocker stud removal/tap alignment tool from Comp Cams made the job easy.

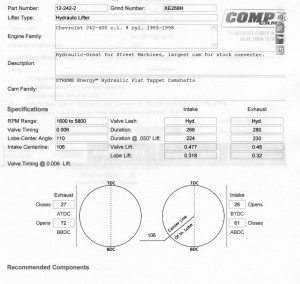

- Upgrade the camshaft and lifters

I needed to add a little more lift and duration to fulling utilize the ported heads. I happened to have a Comp Cams XE268H flat tappet cam on the shelf.

- Increase the size of the carburetor

The last upgrade was increasing the size of the carburetor from a 575 Speed Demon to a 650 Speed Demon.

Budget 350 gets a 50 horsepower tune up “Dyno testing again”

After upgrading all the parts I took the Budget 350 back to the engine dyno.

Click on the link below to watch the engine on the dyno:

Budget 350 dyno pull

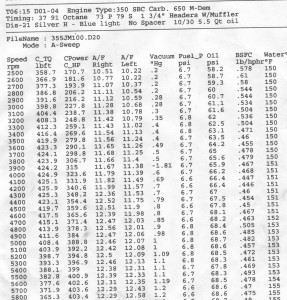

In order to get real world numbers I used the Hooker Super Competition headers and the Magnaflow mufflers from the car it was going in, my 69 Chevelle.

After setting the timing and re-jetting the carburetor the junkyard 350 made 403 horsepower @ 5700 and 426 ft-lb of Torque @ 4200.

Wanting to get all I could out of this combination I tested several carburetor spacers.

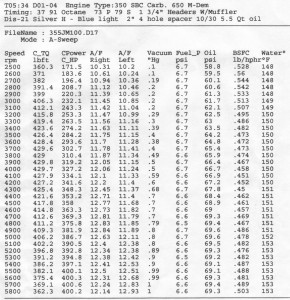

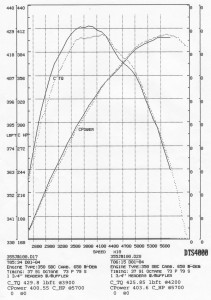

I found the 4 hole 2″ spacer made the best power curve . It made 400 Horsepower @ 5700 and 430 ft-lb torque @ 3900. Not a significant change at the peaks from the non-carb. spacer pulls, however the average torque numbers went up quite a bit from 2500 to 4500. Knowing the car weighs 3500 lb. with the driver that extra torque was worth the loss of horsepower up top.

Here’s a copy of the graph with both dyno pulls. You can see the difference in the torque from 2500 to 4500.

Budget 350 gets a 50 horsepower tuneup “Testing in the real world”

After all the upgrading and dyno testing it was time to test the Budget 350 in the real world. I installed it in the JMacPerformance 69 Chevelle.

A few details on the car: 4:56 gear, 28 x 12.5 x 15 Mickey Thompson ET street rear tires, Turbo 400 transmission, 2800 Stall converter, 6 point roll cage, 3500 lb. with driver.

I ran it at the PSCA “Spring Break Super Show” held March 11th – 13, 2011 @ Auto Club Dragway in Fontana Ca.

It ran a best 12.486 @ 107.43 mph and the engine never went over 6000 RPM. In fact the shift points were set at 5750 RPM.

The Budget 350 is a solid economical Street/Strip engine. It is a good example of what can be achieved with good engine building techniques, focusing on the parts that make power (Camshaft, valve train, and heads), and putting together a combination of parts that work together.