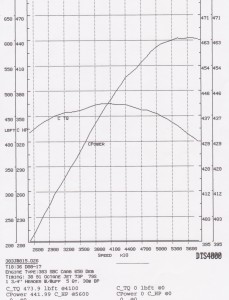

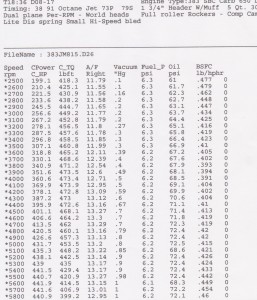

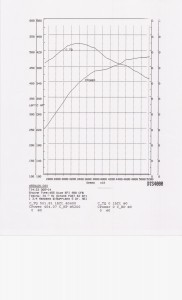

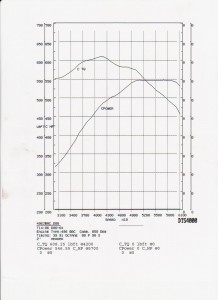

450 Horsepower – 480 LB-FT Torque 396 Big Block Chevy

Block and Cylinder heads

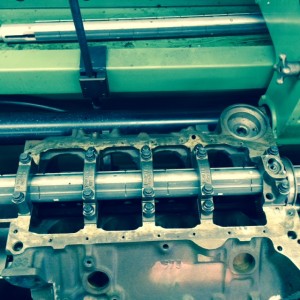

The build started with a rare factory 4 bolt main 396 block # 3855962.

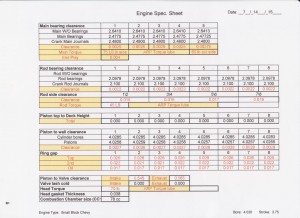

The block received the usual machine work: magnaflux’d , bore and honed .030 over with a torque plate, decked, and line honed.

I always use ARP main bolts for added strength

You can tell it’s a 396 block by the intake valve reliefs machined into the deck to help eliminate cracks all the extra casting flash was ground off

Before

After

The oiling holes were smoothed and lifter valley was cleaned up.

Cylinder heads

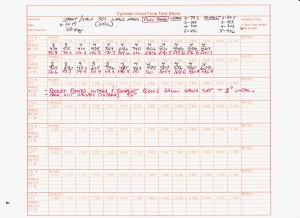

Stock # 3872702 cylinder heads with a 98 cc closed combustion chambers were used. They received magnfux’d, decked, new valve guides, 3 angle valve job, and Manley 2.07″ intake and 1.725″ exhaust stainless steel valves.

Because the 396 has a small 4.125″ bore cylinder I resisted the temptation to install larger valves. I did use a .100″ longer valve to accommodate the taller lift of a bigger camshaft.

The cylinder heads received a pocket porting where the bowl under both valves were opened up, valve guides were narrowed, and the exhaust ports were polished.

In the 60’s gasoline had lead in it, not so much in 2017. To accommodate running on unleaded fuel harden valve seats were also installed.

To ensure no oil gets into the combustion chamber the guides were cut so Viton oil seals could be installed.

The Bottom End

This 396 already had a great factory forged steel crankshaft. It was turned .010 under on both the mains and the rod journals, polished, oil holes were chamfered, and balanced.

Stock size 6.135″ Scat full floating connecting rods with ARP bolts, forged Icon pistons, and Hastings single moly piston rings were used. Piston to wall clearances were set between .0035″ – .004″.

The pistons have a small dome which creates a total of 9.5/1 compression with the 98 cc combustion chambers.

Main and Rod clearances were set to .00275″and .0025″ respectively and the crankshafts end play was set to .005″

The oil pump is a standard volume, standard pressure Mellings. Unless you’re planning on running a 7 quart oil pan or larger a hi-volume pump is not recommended. The oil pump received the usual blue printing to ensure the relief valve worked properly and the cover to gears clearance was correct.

Notice the oil pickup is tack welded to the pump to ensure it does not come loose

The pistons were set at .015″ below the deck

The Valve Train

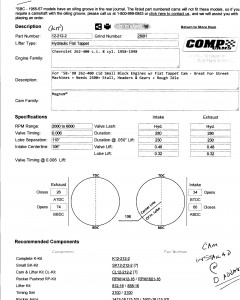

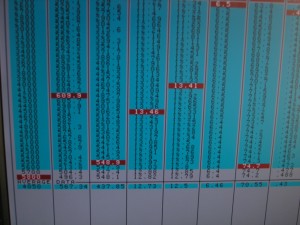

The heart of the valve train is a Comp Cams custom grind billet hydralic roller # 2640-16 Intake .510″ lift 230 @ .050 – exhaust .520″ lift 236 @ .050 on a 110 lobe center.

Note: because this is a 1966 block the rear camshaft main journal and the rear cam bearing both have a groove machined in them. Using a non-grooved camshaft and rear bearing in the earlier block with result in engine failure!!

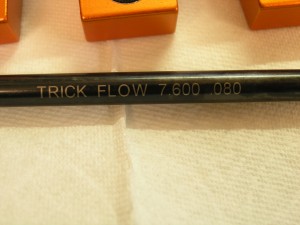

Finishing the rest of the valve train are Comp Cams hydraulic retro-fit roller lifters, Comp Cams one piece push rods, and Scorpion 1.7 ratio roller rocker arms

A double roller timing chain with a Torrington bearing a long with a nylon cam button was installed. Because the block was line honed a .005″ smaller timing chain had to be used.

The cam was set at 2 degrees advanced

Induction, fuel system, and ignition

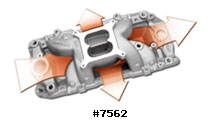

A Quick Fuel 750cfm double pumper carburetor, Weiand duel plan intake manifold, Edlebrock hi volume mechanical fuel pump and a HEI distributor was used.

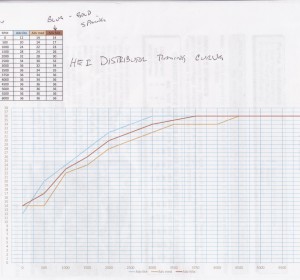

The HEI distributor was recurved to have 14 degrees of timing at idle and 38 degrees of timing at 3800 RPM

This engine has the performance needed to be successful at the drag strip or auto cross but has the manners to be a great street cruiser

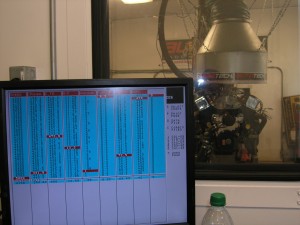

Click on the link below to see and hear it run on the engine stand