455 Oldsmobile Fuel injected “Stump Puller”

The goal with this build was to create an engine with exceptional low RPM manners, run well on 91 octane, and have muscle car performance.

It ended up with over 400 horsepower and over 500 ft-lb torque, all on 91 octane fuel

“Getting to the bottom of the 455 Olds build”

As with all JMac built engines we started the build with the bottom end. I using a stock “F” 455 block, stock iron crankshaft, and stock connecting rods. All the parts were magnifux’d for cracks, the block was bored and honed .030 over with a torque plate, the connecting rods had ARP bolts installed then resized, the crankshaft had the oil holes chamfered, and then had the journals polished.

When most people talk about 455 Oldsmobile engines the subject of a poor oiling system usually comes up. Oldsmobile 455 engines have a history of low oil pressure and bottom end oil starvation, we address both on this build.

Addressing the low oil pressure and oil starvation

I started with a Mellings standard pressure/standard volume oil pump which I blue printed to insure all the clearances were correct, than I added an .080 shim to the spring which adds a little more pressure at idle.

Many people try adding a high volume pump to address the Olds 455’s oiling issues but in stock form these engines have a very poor oil return from the heads to the pan. A high volume oil pump increases the problem by pumping more oil up top and potentially draining the oil pan in the process.

Next I addressed the oiling system in the block. If you take a look at the oil passages in the Olds 455 block they’re quite large. Because of the way the oil flows more of the oil is directed to the camshaft, push rods, and rockers arms leaving less where it’s needed at the bottom end. So I added oil restrictors to the # 2, 3, and 4 main oiling passages between the main and cam bearings. This limits the oil going up top and increases the oiling to the mains bearings.

Next I verified the connecting rod and main bearing clearances were within specification. The rule of thumb is .001″ of clearance for every 1″ of crankshaft journal diameter. However, the Olds 455 has a 3″ main journal diameter and 2.5″ diameter on the rods, that would call for .003″ clearance on the main bearings which is too wide for a street engine, especially one that will run consistently at low RPM. So I tightened the clearances to .0025″ on the mains bearings and .002″ on the connecting rod bearings.

I then addressed the poor oil return from the heads to the pan. I opened up the return holes in the heads, radius the holes, and ground a slight groove in the lifter valley from the heads to the return holes in the block to aid quicker oil return to the pan. I polished the walls of the lifter valley which helps the oil return to the pan quicker.

Finally I added a new 5 quart oil pan along with a crankshaft oil scraper to help keep as much oil in the pan as possible while freeing up a few extra horsepower in the process.

The rest of the bottom end

Olds 455’s are not known for their robust main caps so I added ARP main cap bolts for some added insurance. Forged pistons, moly rings, and clevite bearings finished off the rest of the bottom end along with balancing everything before installation.

“Cylinder heads and valve train”

Cylinder Heads

I started with a set of 455 “G” cylinder heads, I used them because they already have harden exhaust seats installed from the factory which is needed when using unleaded pump gas.

The “G” heads came with a small 2.00″ intake valves so I upgraded to larger stainless steel 2.072″ intake valves and 1.625″ exhaust valves, the seats were cut with a 3 angle valve job. Then the heads were treated to a mild porting where the bowl under the valve seats were opened up. The intake and exhaust ports were smoothed and cleaned up. With the 80cc combustion chamber and dished forged pistons the static compression ratio is 9.25/1 which works well with 91 octane pump gas.

Olds 455 cylinder heads have a history of running hot and cracking between the two center exhaust ports, this is because both inside exhaust ports flow into the crossover port that runs under the intake manifold. To reduce the buildup of heat and to help direct the hot gasses out of the head more quickly I filled the crossover port in the heads with zinc. This greatly reduces the heat that is absorbed in the head which helps increase power and eliminates the potential for heat related cracks.

Camshaft and valve train

Because this engine is going to be used as a freeway cruiser with 3.20 rear end gears and an overdrive transmission the camshaft had to be pretty conservative. A hydraulic flat tappet Comp Cams XE256H was used along with Comp Cams lifters, push rods, valve springs, locks, retainers, and double roller timing chain.

Stock Olds 455’s have pedestal type non-adjustable rockers arms, so a set of adjustable roller tip rocker arms were installed along with Comp Cams push rod guide plates.

“Induction system and ignition”

Induction system

To accent the low RPM drivability an Edelbrock Performer intake manifold was used, this matched the target RPM of the camshaft very well. A FAST EZ fuel injection system was used instead of a carburetor. I have done hundreds of dyno tuning sessions and I have to say the FAST EZ system was by far the best and easiest system I have ever use and tuned!

Ignition system

The ignition system is a basic HEI distributor, I added an upgraded coil and changed the timing curve so a higher initial timing could be used, this again accented the low RPM drivability of the engine. Finishing off the ignition system was a set of MSD 8.5 mm plug wires and Autolite sparkplugs.

“Exhaust system”

A set of long tube 1 3/4″ primary and 3″ collector headers for a cutlass and a pair of Magnaflow mufflers were used during the dyno session.

“400 HP – 500 Ft-Lb Torque

Big Block 455 Oldsmobile Judgement Day”

We bolted the 455 Olds to the DTS engine dyno to see what kind of power it would make. Connecting the FAST EZ EFI system to the engine was actually much easier that I had anticipated, they ready made everything Plug-and-Play. I ran the engine for 20 minutes to break-in of the flat tappet camshaft and allow the EFI system to learn what the engine needed. After a 10 minute cool down I began tuning with a couple of quick low RPM pulls to find the best timing at 36 degrees and insure proper oil pressure. The oil pressure at idle was a solid 30 PSI and climbed to a stable 50 PSI at 2500 RPM.

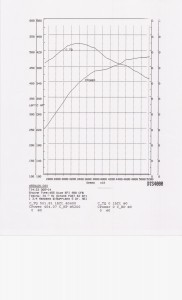

After 8 pulls the engine made 404 Horsepower @ 5200 and a “stump pulling” 521 Ft-Lb torque @ 3300. It made 460 Ft-Lb torque at 2500 and never dropped below 400 Ft-Lb torque from 2500 to 5200 RPM!

Click on the link below to view the dyno pull

455 Oldsmobile 404 Horsepower – 521 Ft-Lb Torque

With that much torque at such a low RPM this engine will make any Street Rod, Muscle Car, or Ski boat run extremely well!