383 Small Block Chevy 440 Horsepower – 473 Ft-Lb Torque

The goal with this build was to make a strong engine that has good street manners and enough power to be competitive at the track or for off-roading.

“Block Prep”

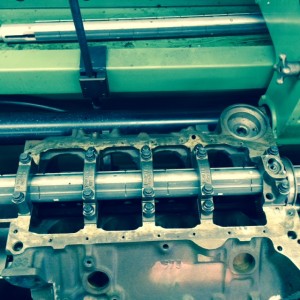

The build started with a good factory 4 bolt main block that was magnifuxed, bored and hone .030″ over with a torque plate, line honed, then decked. All the block casting flash was removed and the oil return holes in the lifter valley were cleaned up and radiused.

The block was cleaned, all the bolt holes chased and chamfered to ensure the heads would sit flush on the deck. The oil galley holes behind the timing chain were tapped and threaded pipe plugs were installed.

The bottom of the cylinder bores were sanded with emery cloth to eliminate the sharp edge to reduce scuffing of the piston skirts

The galley plug under the rear main cap was removed and replaced. Dirt and small metal shavings from the machine work usually hide behind this plug, this is the best way to clean it out

“The Bottom End”

The bottom end needed to handle 600+ horsepower so a SCAT bottom end kit was used. It has a cast steel 3.75″ stroke crankshaft, 6.0″ connecting rods, KB pistons with floating wrist pin, Speed-Pro moly piston rings, and Clevite bearings. All bearings were deburred before installation.

I installed Dura bond performance cam bearings.

The main bearing clearances were checked, all of came in at .0025″. The main cap ARP bolts were torqued to 75 lb-ft on the inner bolts and 65 lb-ft on the outer bolts

The crankshaft end play which was set at .004″

The pistons rings were cut to .026″ top – .022″ Second, .015+” oil ring, The piston to cylinder wall clearances were verified at .0026″ – .028″, the connecting rod bearing clearances were set at .0022″. After installing the pistons on the connecting rods the ARP con-rod bolts were torqued to 45 lb-ft. Connecting rod side clearances were at .017″ – .019″

A standard pressure/standard volume Mellings oil pump and hardened oil pump shaft was used. The oil pump was disassembled, cleaned and clearances were checked before installation The oil pump pickup was tack welded to the pump after the oil pan to pickup clearance was set at 3/8″. A crankshaft oil scraper was installed and the clearances set at .060″

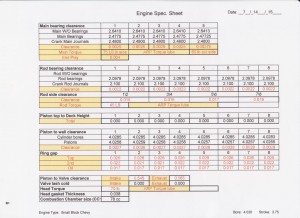

The clearances specification sheet

“Valve Train and cylinder Heads”

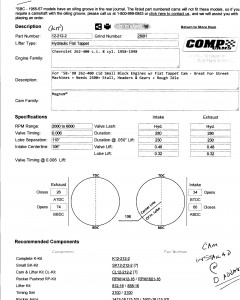

A Comp Cams 12-212-2 valve train kit was used: camshaft, lifters, push rods, valve springs, retainers, and locks. The cam timing was degreed to 2 degrees advanced. The block was line bored so a -.005″ timing chain with a Torrington bearings was installed

“Cylinder Heads”

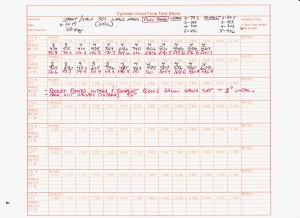

Iron World Product Sportsman II 200 cc cylinder heads were used. They were pocket ported in the bowls below the valve seats and the intake valves received a 52 degree back cut to help increase the low lift flow numbers. Stainless steel 2.02″ intake and 1.60″ exhaust valves were used. The combustion chambers were checked and came in at 78cc. With a flat top piston and zero deck height the static compression ratio was 9.25/1. The heads were placed on the flow bench see the spec sheet below

After checking spring retainer to valve guide seal clearance the valve spring height was set to 1.800″. The rocker arm geometry was checked. Notice: the use of Crane Cams full roller rocker arms and poly locks.

“Induction and Ignition

An Edelbrock RPM Performer intake manifold was match ported to the heads and the dividing bar between the dual planes was contoured to ensure equal distribution to all the cylinders. You can see the intake runners before and after match porting.

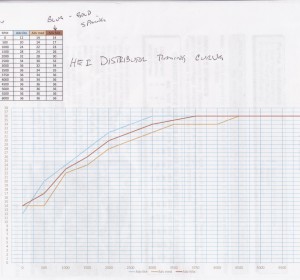

“Ignition system”

An aftermarket HEI distributor was used. To help increase torque and low end horsepower I recurved the distributor timing. I closed up the mechanical advance slot to reduce the distributors total advance so more initial timing can be added at a lower RPM. About .080″ was removed from the slot to reduce the total mechanical timing by 6 degrees. The initial timing can be set at 14 degrees instead of the usual 8-10 degrees while keeping the total timing at 38 degrees. I installed lighter advance springs to have all timing in by 3500 RPM.

On the dyno this added 8-10 Lb-ft of torque between 2500 to 3500 RPM

“Carburetion”

A Mighty Demon 650 CFM double pumper carburetor with Idle and high speed air bleed jets was used

An Edelbrock 650 carburetor was initially used during the dyno testing, the Demon carburetor was worth 20 horsepower 20 lb-ft torque throughout the entire RPM range.

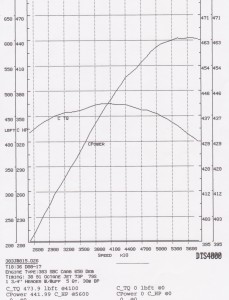

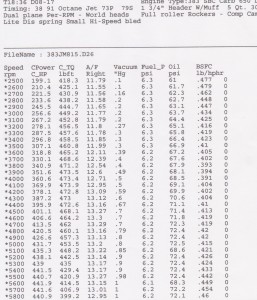

“Judgement day”

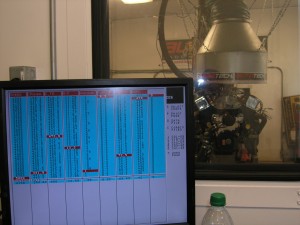

The 383 was tested on a DTS engine dyno at Saddleback College in Mission Viejo, Calif. After a 20 minute initial break-in I did a few low rpm pulls to set the timing to 38 total degrees. I tuned the carburetor with a few main and high speed air bleed jet changes.

It made 473 lb-ft torque @ 4100 and 442 horsepower @ 5600. It made 418 lb-ft torque @ 2500 and never made under 400 lb-ft torque through the entire rpm range.

Click the link below to see a close up of the engine on the dyno

440 HP – 473 TQ Street 383 close up on the dyno

This engine is the best of all worlds! With it’s pump gas friendly 9.25/1 compression it can be a daily driver. 442 horsepower and 473 lb-ft of torque will get the average muscle car or street rod into the 11’s at the drag strip or dominate the off road in a 4 x 4 truck.