383 Small Block Chevy 560 Horsepower pump gas

JMac Performance put together a 550 Horsepower pump gas 383 Small Block Chevy. Here are the details from the parts selection to the dyno testing.

550 Horsepower pump gas 383 Small Block Chevy “Parts selection”

I started the build with a good factory block; a 4 bolt main roller block out of a mid 90’s Chevy truck. The mid 90’s truck blocks have thicker castings, 1 piece rear main seal, and are fitted with hydraulic roller camshafts from the factory.

Knowing the 383 would be pushed to its performance limit I used all forged bottom end parts:

CP Bullet pistons, forged 3.75″ stroke crank, and 6.0″ forged connecting rods.

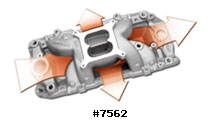

The key to making good horsepower is in the heads, camshaft, intake manifold, and carburetor. I used a set of Airwolf 220e’s, a Dr. J’s match ported single plane intake manifold, custom ground hydraulic roller camshaft from Iskendrian, and a 750 Mighty Demon carburetor.

550 Horsepower pump gas 383 Small Block Chevy “Block Prep”

I had the block cleaned (hot tanked), bored and honed .030 over w/torque plate, decked, and line honed. I installed new Durabond performance cam bearings. The performance cam bearings are a little harder that standard bearings so they can with stand higher loads brought on by higher valve spring PSI. The block was thoroughly cleaned with soap and pressured hot water. All the bolt holes were cleaned with a thread chaser and the camshaft oil galley plugs were taped for allen head plugs.

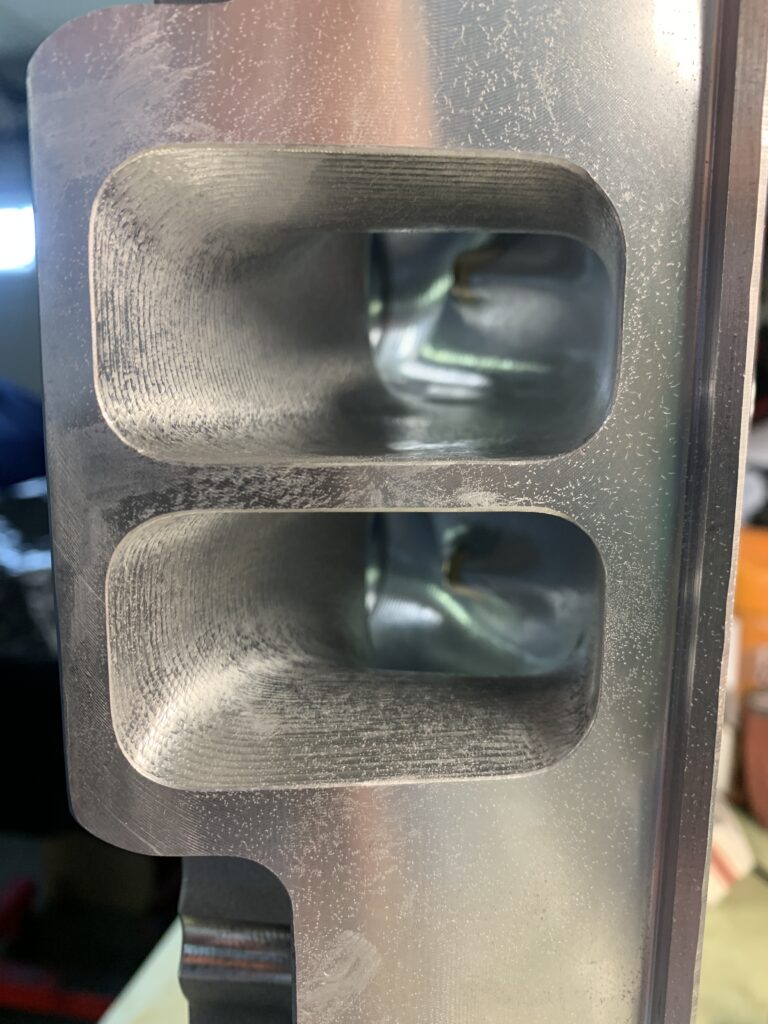

The bottom of the cylinders and the oil pan rail had to be clearanced to make room for the 3.75″ stroke crank and 6.0″ rods. The bottom of the cylinders were also chamfered to help reduce friction and piston skirt scuffing.

To ensure maximum flow out of the oil pump I put a radius on the rear main cap oil hole.

550 Horsepower pump gas 383 Small Block Chevy “bottom end work”

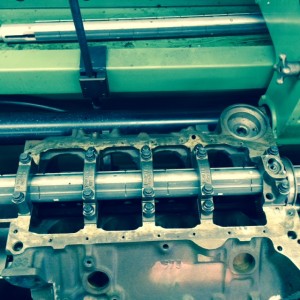

To ensure the 383 will live a long and happy life I mocked up the bottom end and checked all the clearances.

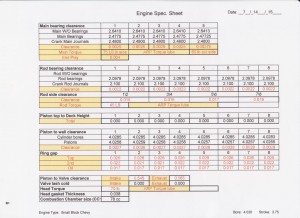

I started with the main journals. After having the crank polished I got 2.477″ on the main caps and 2.48″ on the crank giving us a solid .003″ clearance. I did the same with the connecting rods; 2.097″ on the rod ends and 2.100″ on the crank giving us the same .003″ clearance.

Next I checked the piston to cylinder wall clearance; 4.026″ on all the pistons, 4.0302″-4.0303″ on the cylinder walls giving us a little over .004″ piston to cylinder wall clearance. All the piston rings were hand filed to top -.019″, second – .023″ , oil ring – .015″ .

Note: To help reduce internal friction and free up a little extra Horsepower the CP Bullet pistons had a 1.5 mm, 1.5 mm, 3.0 mm ring pack.

Before torquing everything in place I set the crank end play at .005″

After all the clearances checked out I assembled everything together torquing the mains to 65 ft-lb. and the rods bolts to 63 ft-lb. Notice I used ARP bolts on both the rods and the main caps.

Double checking the deck height we got -.005″ out of the hole. This set us up with a quench of .036″ which helps reduce the chance of detonation on 91 octane fuel.

550 Horsepower pump gas 383 Small Block Chevy “Oiling system”

Leaving nothing to chance I always disassemble the oil pump (Mellings 55HV) and check all the clearances. Notice the hardened oil pump shaft and welded on oil pump pick up.

To help reduce windage and free up some more Horsepower I used a 6 qt. oil pan with a built in oil scraper and windage tray. before bolting on the oil pan I set the oil pump pick to oil pan clearance to 3/8″.

550 Horsepower pump gas 383 Small Block Chevy “Valve Train”

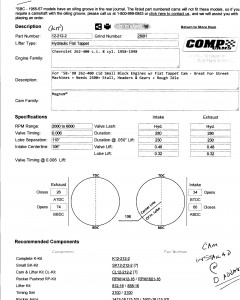

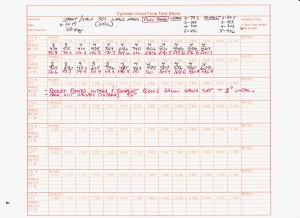

At the heart of this 383 is a list of quality valve train components, starting with the custom Iskendian hydraulic roller camshaft. It is a single pattern camshaft with .595 lift, 244 degrees of duration @ .050 and an advertised duration of 290 all on a 110 lobe center.

Because of the roller block the factory style hydralic roller lifters (I used Comp Cam lifters), guide plates, and holder were used in place of retro fit lifters.

To take advantage of the free flowing heads I wanted as much lift as possible so I installed Harland Sharp1.6 ratio rocker arms.

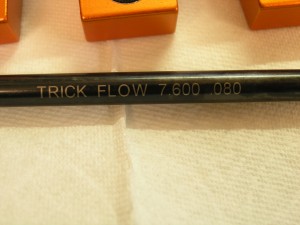

Using custom length Comp Cam one piece push rods allowed for the proper rocker arm geometry.

550 Horsepower pump gas 383 Small Block Chevy “Completed”

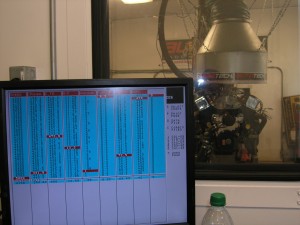

Here’s the completed engine waiting to be tested on the DTS dyno.

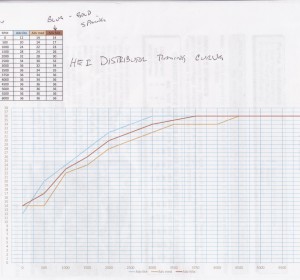

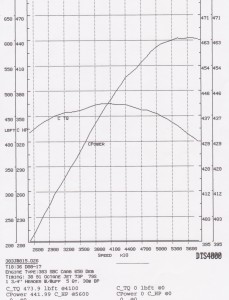

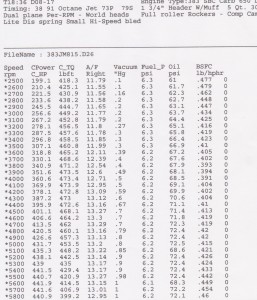

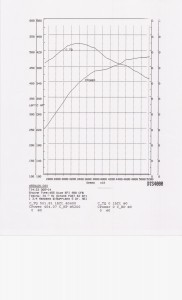

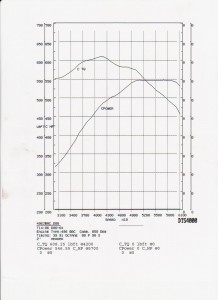

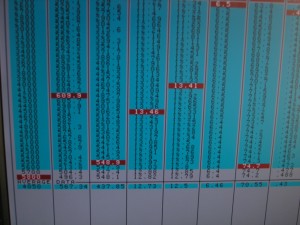

After completing a series of tuning pulls here’s a copy of the final numbers

558 Horsepower @ 6300 – 510 ftlb @ 5000