450 Horsepower – 500 Lb-Ft Torque Ford 351W (393 Stroker)

JMac Performance put together a 450 Horsepower – 500 Lb-Ft torque 9.75/1 Fuel injected 351 Windsor/393 stroker Small Block Ford. The goal with this build was low RPM high Torque that could move a 4000 pound 56′ Mercruiser, run on pump gas, and have the street manners to be a daily driver.

Ford 351W (393 Stroker) “The Foundation”

I started the build with a mid-1980’s non-roller 351 W, 2 bolt main, 1 piece rear main seal block. I chose the non-roller block because some of the newer late 80’s/early 90’s roller blocks can have stress cracks in the valley above the cam bearings. The non-roller 351W blocks can be easlly converter to roller blocks and have proved to be crack free.

The block recieved the usual hot tank, magniflux, .030 over bore and hone with a torque plate, line hone, and decking. I also ground off all the extra casting flash and opened up the oil holes in the lifter valley to ensure the oil returns to the oil pan without restriction.

Before – from the factory

After it has been opened up

Grinding off the excess casting flash makes the engine easier to work on and helps eliminate stress cracks.

Ford 351W (393 Stroker) “Bottom End”

Over 500 Lb-Ft of torque can put quite a strain on the main caps. A main cap girdle was used along with ARP main cap bolts to ensure everything stayed tight and in-line.

Because of the 3.850″ stroke of the crankshaft the main gridle needed to be clearanced. The throw of the crankshaft and the big end of the connecting rods need a minimum of .060 clearance.

A forged SCAT 3.850″ stroke crankshaft, forged SCAT 6.2″ connecting rods with ARP bolts, forged 4.030″ ICON Pistons, Speed-pro single moly piston rings, and Cleveite bearings were used to complete the bottom end.

Ford 351W (393 Stroker) “Oiling System”

A mellings high volume oil pump was used to keep the bottom end well lubed. The main gridle needed to be clearanced to ensure a proper fit between it and the oil pump. To keep the integrity of the oil pump it’s better to grind the main gridle not the oil pump.

From the factory the oil holes that drain from the cylinder heads back to the oil pan can sometimes be mis-aligned. To ensure oil flows freely the holes were opened up and chamfered.

With all JMac Performance engine builds the oil pump is disassembled to ensure all clearances are correct and to verify the relief valve and pressure spring work freely.

Ford 351W (393 Stroker) “Cylinder Heads and Induction System”

AFR Renegade 185 cc heads were used, they are CNC ported and are an exceptional cylinder head. A larger cylinder head would have made more horsepower, However the customer stressed they wanted low RPM torque over higher RPM horsepower. The smaller cylinder heads help increase the intake velocity at lower RPM thus creating a more responsive and higher torque engine.

Because the customer wanted a maintenance free fuel system with maximum drivability the FAST EZ fuel injection system was used. It is a self learning, extremely easy system to install and use and no tuning is needed!

I used an Edelbrock RPM Performer dual plane intake manifold. It matched the operating RPM of the engine very well, from 2500 – 6500 RPM. I have found that most fuel injection systems do not like full dual plane intake manifolds. So, about 1/2″ was removed from the intake manifolds center divider to help both banks equalize better.

Before After

Ford 351W (393 Stroker) “Valve Train”

As I mentioned earlier a non-roller block was used over the crack prone later roller blocks. A hydraulic roller camshaft and valve train was to be used so I convered the block to a roller type by installing a Comp Cams conversion kit. It allows the use of less costly non-link bar lifters. A lifter valley “spider” and “wish bone” alignment links are adapted to the block.

Two small 1/4″-20 holes are drilled and tapped into the lifter valley floor to hold down the lifter “Spider”. The edge of the lifter valley where the lifter wish bones links sit are clearanced to ensure full movement.

A set of Dura-Bond high performance camshaft bearing were installed.

Although it is an non-roller block the roller thrust plate can still be used to keep the camshafts end play in check. Because the block was line honed a -.005 smaller double roller timing chain with a needle bearing thrust washer was used. Notice the flat head allen screws used to hold the thrust plate in place, they are needed to create a flat surface for the timing chain thrust bearing.

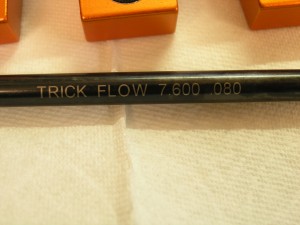

To top of the valve train a set of Trickflow 7.600″ .080″ thick push rods were used along with a set of 1.6 ratio Hardland Sharp full roller rocker arms.

Ford 351W (393 Stroker) “Test run”

With the engine complete all that was needed is a quick test run on the engine stand to ensure all systems worked properly. After setting the intial parameters on the FAST EZ fuel system the engine started right up. The timing was set to 14 degrees at idle of 850 RPM and 36 degrees total all in at 3500 RPM. As the engine ran I could see the air/fuel ratio’s begin to reach their target settings. The engine is ready to install in the 56″ Mercury Mercuriser and after about a tank of fuel will be fine tuned for many years of trouble free driving.

Click here to see the engine on the run stand

450 Horsepower – 500 Lb-Ft Torque Ford 351w / 393 stroker engine.

Contact John@JMacPerformance.com if you’d like more details on this engine build.