Budget 350 build “The Beginning”

I decided it was time to rebuild the small block 350 that had been hiding in the corner of my garage for over 30 years. It was originally purchased in 1978 as a project engine for my dad’s 1930 Model A coupe. After some thought and a look at the raising gas prices he decided to stick with his very reliable, more economical 283.

Looking over the VIN number it was discovered our 350 was out of a 1971 Corvette (VO609CJK). I was hoping to find some high performance parts (Steel crank and a 4 bolt main) underneath the 30+ years of grease and dust. Unfortunately it was a 2 bolt main block, stock cast iron crank and, slightly above average 3973487 casting heads. Not what I had hoped for be still a solid foundation for a nice street engine.

Looking over the VIN number it was discovered our 350 was out of a 1971 Corvette (VO609CJK). I was hoping to find some high performance parts (Steel crank and a 4 bolt main) underneath the 30+ years of grease and dust. Unfortunately it was a 2 bolt main block, stock cast iron crank and, slightly above average 3973487 casting heads. Not what I had hoped for be still a solid foundation for a nice street engine.

Budget 350 build “Bottom end work”

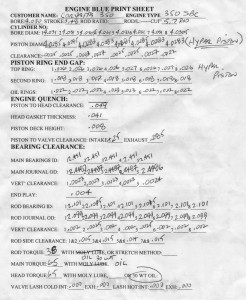

After the usual tear down and inspection it was determined the 350 needed some work. It needed to be bore .030 over, the connecting rods needed to be resized, the block needed to be decked, the crank needed to be polished, and the mains were line honed . Because the pistons needed to be replaced I decided to go with a slightly upgraded Keith Black hypereutectic piston and moly rings. To top off the short block a new 8″ stock harmonic balancer was installed and the rotating assembly was balanced. With the exception of the pistons the bottom end was stock.

Budget 350 build “A little head work”

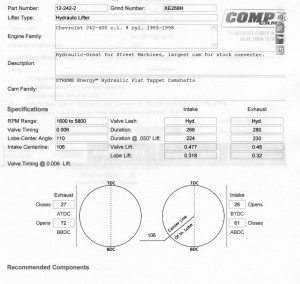

looking over the cylinder heads they also needed some updating. First thing I did was to have the heads decked about .020″. (with the new pistons the compression ratio was now 9:1) Then I updated to new stainless steel ferrea’s (1.94″ intakes, 1.50″ exhaust) valves and had them cut with a 3 angle valve job. To help with the low lift flow numbers I placed a 52 degree back cut on all the valves after the valve job was complete. When the 487 heads were designed leaded fuel was the norm. Knowing this 350 would never see leaded fuel I had hardened valve seats installed on both intake and exhaust making them compatable with unleaded fuel. The stock exhaust valve rotating retainers were removed and upgraded valve springs, steel retainers, and clip were installed. To complete the cylinder head upgrade I gave them some pocket porting. I opened up the bowl about 1″ under the valve seat, reduced the valve guide, blended in the new hardened seats, opened up the complete exhaust port, and cleaned up the casting inside the intake port.

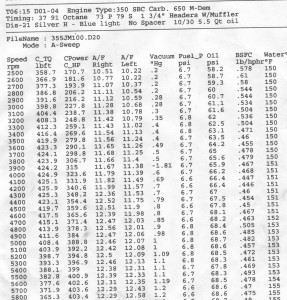

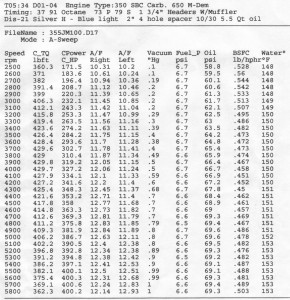

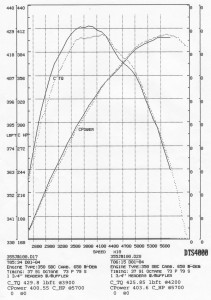

Budget 350 build “Dyno testing”

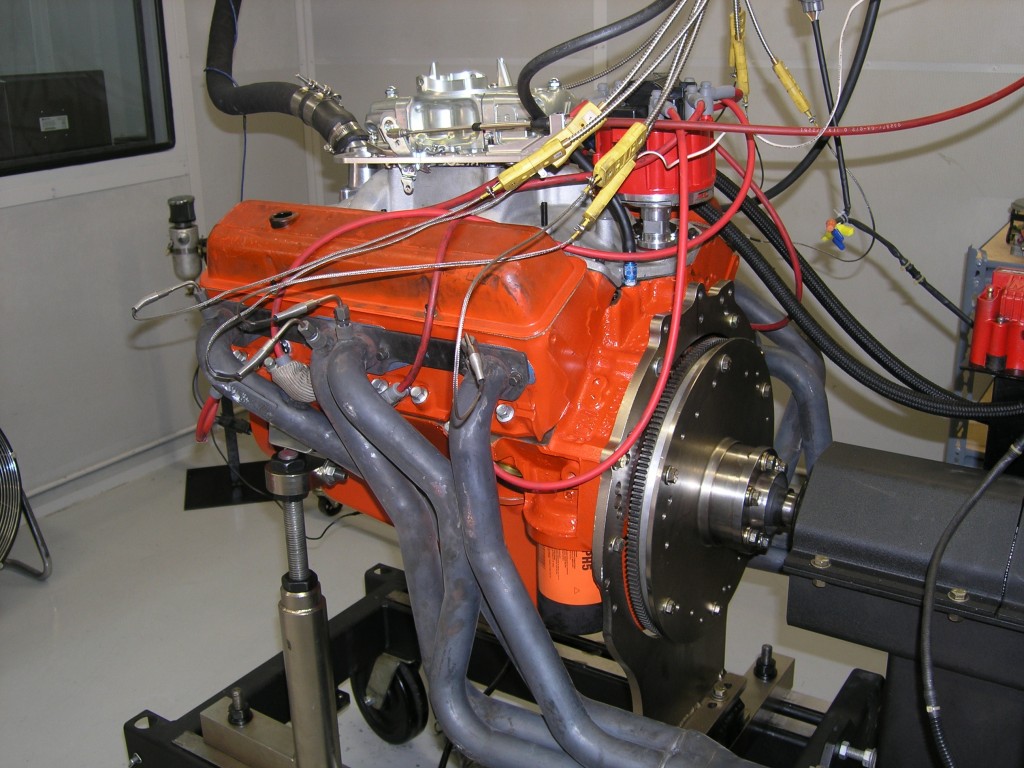

To complete the build the 350 was bolted together using Fel Pro gaskets, a Mellings standard PSI and volume oil pump, 6 qt.oil pan, stock push rods and rocker arms, Edelbrock Performer RPM intake manifold, MSD street fire HEI distributor, and a Demon 625 carburetor.

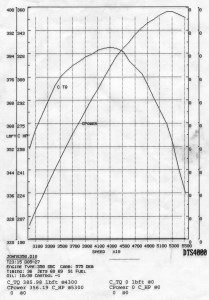

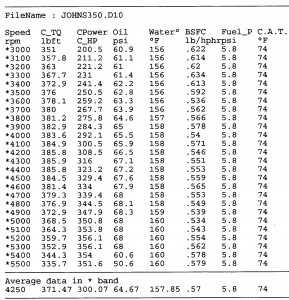

Performing the usual break-in and tuning on the DTS powermark dyno I was able to get the Budget 350 to pump out 356 Horsepower @ 5300 RPM and 386 lb-ft Torque @ 4300 RPM. Not bad considering this engine was rated at 270 Horsepower new from the factory.